Surgical Implant Guides: A Comprehensive Overview (Updated 01/09/2026)

Surgical implant guides enhance precision in implant dentistry, offering solutions from fully guided to freehand approaches, and are crucial for predictable outcomes.

Surgical implant guides represent a significant advancement in restorative and surgical dentistry, dramatically improving the accuracy and predictability of implant placement procedures. Historically, implant placement relied heavily on clinical experience and two-dimensional planning. However, the integration of digital technologies, like CBCT scanning and sophisticated software, has enabled the creation of patient-specific guides.

These guides facilitate precise osteotomies and implant positioning, minimizing deviations from the pre-operative plan. The challenge lies in navigating the diverse landscape of guide types and technologies. Clinicians must understand the nuances of each approach – fully guided, pilot guided, or freehand – to select the optimal solution for each individual case, ensuring successful and long-lasting implant restorations.

What is a Surgical Implant Guide?

A surgical implant guide is a meticulously crafted prosthetic device designed to assist clinicians during dental implant surgery. Essentially, it’s a physical template that fits securely over the patient’s jaw, providing pre-determined pathways – or sleeves – for drill guidance. These sleeves dictate the precise angle and depth of osteotomy preparation, ensuring accurate implant placement according to a pre-planned digital treatment plan.

The guide’s contact surface conforms to the patient’s unique anatomy, offering stability and facilitating a predictable surgical workflow. It represents the culmination of digital planning, CBCT data, and fabrication technology, translating a virtual plan into a tangible surgical aid.

The Importance of Guide Classification

Clinicians often face challenges when interpreting research on surgical implant guides due to broad categorizations. Observing outcomes across vastly different guide types obscures meaningful comparisons. More specific and descriptive classifications are vital for understanding guide performance in various clinical scenarios.

For instance, studies often compare implant placement using navigation systems, laboratory guides, or even freehand techniques. Distinguishing between fully guided, pilot guided, and freehand approaches is crucial, particularly for those new to implant dentistry. Accurate classification allows for targeted evaluation and informed decision-making.

Fully Guided vs. Pilot Guided vs. Freehand Guided

Surgical guides vary significantly in their level of control. Fully guided systems dictate both entry point and depth, offering maximum precision. Pilot guided guides provide initial direction, allowing for some clinician discretion during osteotomy preparation. This approach balances control with tactile feedback.

Conversely, freehand techniques rely entirely on the surgeon’s skill and experience, lacking physical guidance. Comparisons between these methods are common in research, highlighting the benefits of guided approaches, especially for less experienced clinicians. Understanding these distinctions is key to selecting the appropriate technique.

Technologies Used in Surgical Guide Fabrication

Currently, two primary technologies dominate surgical guide creation: subtractive technology (milling) and additive technology (3D printing). Milling involves removing material to form the guide, while 3D printing builds it layer by layer. Both methods yield acceptable results, but 3D printing often excels in detail and recreating complex angles.

Many implant planning softwares are specifically calibrated for 3D printers, fostering a seamless workflow and enhancing guide quality. The choice between these technologies impacts precision, passive fit, and the ability to achieve desired implant positioning.

Subtractive Technology (Milling)

Subtractive technology, specifically milling, represents a traditional approach to surgical guide fabrication. This process involves starting with a solid block of material and precisely removing portions to achieve the desired guide shape. While capable of producing functional guides, milling can sometimes be limited in its ability to replicate intricate geometries or extreme angles.

Even with advanced 5-axis milling machines, achieving certain designs can be challenging. Despite these limitations, milled guides remain a viable option, offering a reliable method for creating accurate surgical aids.

Additive Technology (3D Printing)

Additive technology, or 3D printing, has revolutionized surgical guide fabrication. Unlike subtractive methods, 3D printing builds guides layer by layer from a digital design. This allows for the creation of complex geometries, intricate details, and the reproduction of challenging angles that may be difficult or impossible to achieve with milling, even utilizing 5-axis systems.

The precision and detail offered by 3D printing contribute to improved passive seating and overall guide quality, making it a preferred method for many clinicians.

Advantages of 3D Printed Guides

3D printed surgical guides offer several key advantages over traditionally manufactured options. They excel in recreating complex angles and delivering superior detail, crucial for precise implant placement. Furthermore, most contemporary implant planning software is specifically calibrated for use with 3D printers.

This seamless integration fosters an interconnected workflow, resulting in consistently high-quality guides. The ability to produce guides with exceptional passive seating further enhances their clinical effectiveness and predictability during surgical procedures.

Calibration with Implant Planning Software

Precise calibration between implant planning software and the chosen fabrication technology is paramount for surgical guide accuracy. Most current implant planning platforms are specifically designed and calibrated to work seamlessly with 3D printing processes.

This interconnected workflow ensures that the virtual plan translates accurately into the physical guide. Proper calibration minimizes discrepancies and maximizes the predictability of implant placement. Regular validation and adherence to manufacturer guidelines are essential for maintaining optimal calibration and achieving reliable results.

Types of Surgical Guides Available

A diverse range of surgical guides caters to varying clinical needs. Standard surgical guides offer full coverage and guidance for multiple implant placements. Pilot surgical guides provide initial guidance, often used for single-tooth implants or initial stages of rehabilitation.

Multiple unit surgical guides facilitate precise placement of several implants in a defined area, while full arch surgical guides support complete arch reconstruction. Selecting the appropriate guide type depends on case complexity, clinician experience, and desired level of control.

Standard Surgical Guides

Standard surgical guides represent a comprehensive approach to implant placement, offering complete coverage and guidance throughout the entire procedure. These guides typically feature sleeves that dictate the angulation and depth for each intended implant site, ensuring high accuracy. They are particularly well-suited for complex cases involving multiple implants or full-arch rehabilitation, providing a stable and predictable framework.

Their design facilitates a fully guided workflow, minimizing deviations and maximizing restorative outcomes. Clinicians benefit from enhanced control and reduced surgical risks when utilizing standard surgical guides.

Pilot Surgical Guides

Pilot surgical guides offer a streamlined approach to implant placement, focusing on initial osteotomy guidance. Unlike standard guides providing full sleeve coverage, pilot guides typically feature smaller openings, directing the initial drill but allowing for adjustments during subsequent drilling stages; This offers a balance between control and flexibility, particularly beneficial for clinicians gaining experience with guided surgery.

They are ideal for cases where minor adjustments are anticipated or when a less restrictive approach is desired, providing a stepping stone towards fully guided procedures.

Multiple Unit Surgical Guides

Multiple unit surgical guides are designed for the simultaneous placement of several implants, commonly utilized in full arch rehabilitation cases. These guides incorporate sleeves for each planned implant position, ensuring accurate angulation and depth control during osteotomy preparation. They streamline the surgical workflow, reducing operative time and enhancing predictability when restoring multiple missing teeth.

Precision is paramount with these guides, as cumulative errors can significantly impact the final prosthetic outcome, demanding meticulous digital treatment planning and fabrication.

Full Arch Surgical Guides

Full arch surgical guides represent a sophisticated approach to complete-arch implant reconstruction, facilitating the precise placement of numerous implants in a single surgical intervention. These guides are meticulously designed based on comprehensive digital treatment planning, integrating CBCT scans and prosthetic designs. They offer exceptional control over implant position, angulation, and depth, crucial for achieving optimal prosthetic support and function.

Glidewell provides a full range of guided surgical solutions needed to perform most implant procedures, including full arch cases.

Materials Used in Surgical Guide Construction

Surgical guide fabrication utilizes diverse materials, each offering unique properties. Acrylic resins are commonly employed due to their ease of processing and cost-effectiveness, though they may exhibit lower durability. Polycarbonate provides enhanced strength and rigidity, improving guide stability during surgery. However, PEEK (Polyether Ether Ketone) is gaining prominence, offering biocompatibility, high strength, and excellent chemical resistance.

The choice depends on factors like desired precision, surgical complexity, and budget considerations, impacting the overall quality and longevity of the guide.

Acrylic Resins

Acrylic resins represent a frequently utilized material in surgical guide construction, primarily due to their affordability and straightforward processing characteristics. These materials allow for relatively easy fabrication and modification, making them accessible for many dental laboratories. However, it’s important to acknowledge that acrylic resins generally exhibit lower mechanical strength and durability compared to alternatives like polycarbonate or PEEK.

Consequently, they may be less suitable for complex cases demanding exceptional rigidity or prolonged surgical use.

Polycarbonate

Polycarbonate emerges as a robust and widely favored material for crafting surgical implant guides, celebrated for its superior strength and impact resistance. This thermoplastic polymer demonstrates excellent dimensional stability, crucial for maintaining accuracy during surgical procedures. Polycarbonate guides offer a balance between rigidity and slight flexibility, allowing for secure seating on the patient’s jaw without undue stress.

Its transparency also facilitates visual confirmation of implant placement during surgery, enhancing precision and control for the clinician.

PEEK (Polyether Ether Ketone)

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic polymer gaining prominence in surgical implant guide fabrication due to its biocompatibility and mechanical properties. Exhibiting excellent chemical resistance and strength comparable to some metals, PEEK offers a viable alternative for demanding surgical applications. Its radiolucency minimizes artifact during CBCT scans, aiding in accurate treatment planning and post-operative assessment.

Furthermore, PEEK’s flexibility allows for better adaptation to complex anatomical structures, enhancing guide fit and stability.

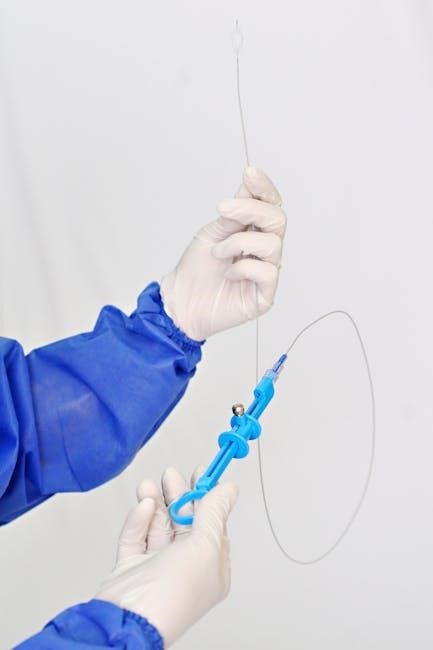

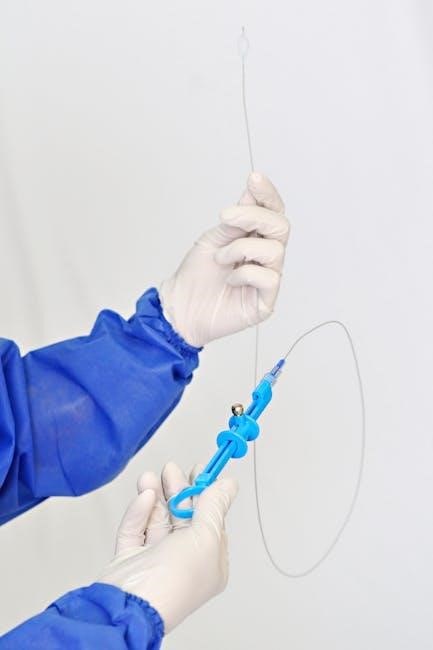

The Surgical Guide Workflow

The surgical guide workflow begins with Digital Treatment Planning (DTP), utilizing advanced software to precisely plan implant placement. This planning is then integrated with CBCT Scan data, providing a detailed 3D representation of the patient’s anatomy. Following this, the guide design and fabrication phase commences, leveraging technologies like milling or 3D printing to create a physical guide.

Glidewell’s DTP team supports dentists throughout this process, offering a comprehensive range of guided surgical solutions.

Digital Treatment Planning (DTP)

Digital Treatment Planning (DTP) is the cornerstone of modern surgical implant guide fabrication. It allows clinicians to visualize and plan implant placement with exceptional accuracy in a virtual environment. This process involves utilizing specialized software to analyze patient-specific data, derived from CBCT scans, to determine optimal implant positioning, angulation, and depth.

Glidewell’s DTP team provides dentists with the tools and expertise needed to navigate this crucial step, ensuring predictable and successful implant outcomes.

CBCT Scan Integration

CBCT (Cone Beam Computed Tomography) scan integration is fundamental to accurate surgical implant guide creation. These scans provide a detailed three-dimensional representation of the patient’s jawbone, including bone density, nerve locations, and existing anatomical structures. This data is then imported into specialized planning software, forming the basis for virtual implant placement.

Precise CBCT integration ensures the surgical guide is tailored to the patient’s unique anatomy, maximizing safety and predictability throughout the implant procedure, and enabling optimal outcomes.

Guide Design and Fabrication

Following Digital Treatment Planning (DTP) and CBCT integration, the surgical guide design phase begins. Software allows clinicians to virtually position implants, considering factors like angulation and depth. Once finalized, the design is prepared for fabrication using either subtractive technology – milling – or additive technology – 3D printing.

3D printing often yields superior detail and passive seating, accommodating complex angles. Many implant planning softwares are calibrated specifically for 3D printers, streamlining workflow and enhancing guide quality.

Accuracy and Precision of Surgical Guides

Achieving optimal accuracy with surgical guides relies on several interconnected factors. Guide design, fabrication technology (milling or 3D printing), and the calibration of implant planning software all play critical roles. Variations in material shrinkage during fabrication, or inaccuracies in the initial CBCT scan, can impact precision.

Studies evaluating CAD/CAM guides highlight the importance of meticulous workflow adherence. While guides generally improve accuracy compared to freehand techniques, understanding potential error sources is vital for successful implant placement.

Factors Affecting Guide Accuracy

Several elements influence the accuracy of surgical implant guides. CBCT scan quality is paramount; artifacts or poor resolution compromise planning. Material selection impacts stability and potential deformation during surgery. Fabrication method – subtractive milling versus additive 3D printing – introduces varying levels of detail and passive fit.

Software calibration with the chosen printer is crucial for predictable results. Clinician technique, including guide seating and drill preparation, also affects precision. Recognizing these factors allows for proactive mitigation of potential inaccuracies.

Clinical Applications of Surgical Guides

Surgical guides demonstrate versatility across various implant scenarios. Single tooth implants benefit from precise placement, optimizing aesthetics and function. Full arch rehabilitation leverages guides for accurate prosthetic support, crucial for complex cases requiring multiple implants. Guides aid clinicians new to implant dentistry, enhancing confidence and predictability.

They streamline workflows, reducing surgical time and minimizing deviations from the digital plan. Glidewell’s solutions cater to diverse needs, enabling informed decisions for optimal patient outcomes and restorative success.

Single Tooth Implants

For single tooth implants, surgical guides are invaluable for achieving optimal positioning, crucial for both functional and aesthetic success. Precise guide utilization minimizes the risk of damaging adjacent teeth or vital structures during osteotomy preparation. This is particularly important when dealing with limited interproximal space or compromised anatomical landmarks.

Guides ensure accurate implant angulation, facilitating ideal prosthetic emergence profiles. They contribute to predictable restorative outcomes, enhancing long-term implant stability and patient satisfaction, even for clinicians newer to implant procedures.

Full Arch Rehabilitation

Full arch rehabilitation demands exceptional precision, making surgical guides indispensable. These guides facilitate the placement of multiple implants with consistent angulation and depth, vital for supporting full-arch prostheses. Utilizing guides minimizes surgical time and reduces the potential for complications associated with freehand techniques.

Accuracy is paramount in achieving proper occlusal relationships and prosthetic stability. Guides, especially those created with calibrated implant planning software and 3D printing, ensure predictable results and streamline the restorative process, benefiting both clinician and patient.

Future Trends in Surgical Implant Guide Technology

Future advancements in surgical implant guide technology center around enhanced integration with navigation systems, offering real-time feedback during surgery for dynamic adjustments and improved accuracy. Biomaterial research focuses on developing guides with improved biocompatibility and mechanical properties, potentially incorporating antibacterial agents.

Expect to see more sophisticated software capable of predicting soft tissue behavior and optimizing implant placement accordingly. Personalized guides, tailored to individual anatomical variations, will become increasingly common, maximizing precision and minimizing risks.

Navigation System Integration

Integrating navigation systems with surgical implant guides represents a significant leap forward in precision dentistry. Combining the pre-operative planning of guides with the real-time feedback of navigation enhances accuracy, particularly in challenging cases with limited visibility or anatomical complexities.

This synergy allows clinicians to dynamically adjust to unforeseen circumstances during surgery, ensuring optimal implant placement. Navigation systems verify guide seating and provide guidance during osteotomies, minimizing deviations from the planned trajectory and improving overall predictability.

Biomaterial Advancements

Ongoing research focuses on refining biomaterials used in surgical guide construction, aiming for enhanced biocompatibility, durability, and precision. Beyond traditional acrylic resins, polycarbonate, and PEEK, investigations explore novel polymers and composite materials offering improved mechanical properties and sterilization resistance.

These advancements seek to minimize guide deformation or degradation during surgical procedures, ensuring accurate implant placement. Furthermore, biomaterial innovations may facilitate the creation of guides with integrated antimicrobial properties, reducing the risk of post-operative complications and enhancing patient safety.